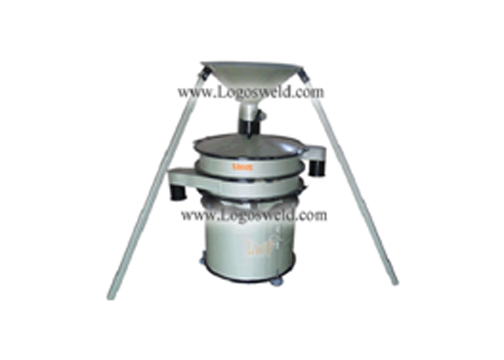

FLUX SIEVING MACHINE

FLUX SIEVING MACHINE

Sieving machine is used for sieving the flux of raw materials

Description

Sieving machine is used in welding electrode plant for sieving the flux or Raw materials. It consist of two chambers. One is to collect the waste materials and another one is to collect the required mesh materials. Mesh inside can be changed as per our requirement. Standard machinery for all the capacity

WELDING ELECTRODE MACHINERY

- Dry Mixer

- Dry Mixer Double Cone Blender

- Wet Mixer

- Wire Straightening & Cutting Machine

- Briquetting Press/ Slug Press

- Wire Feeder Havelock with VFD

- Extruder Horizontal

- Extruder Vertical

- Conveyor With VFD

- Online Printing Unit

- Baking Oven Low & High Temperature

- Wet Flux Reclamation Machine

- Shrink Wrapping Machine Carton Box

- Wire Washing Machine

- Broaching Machine

- Wire Stripping Machine

- Wire Cleaning Machine

- Flux Sieving Machine

- Microscope

- Profile Projector

- flux Cored Wire Machine