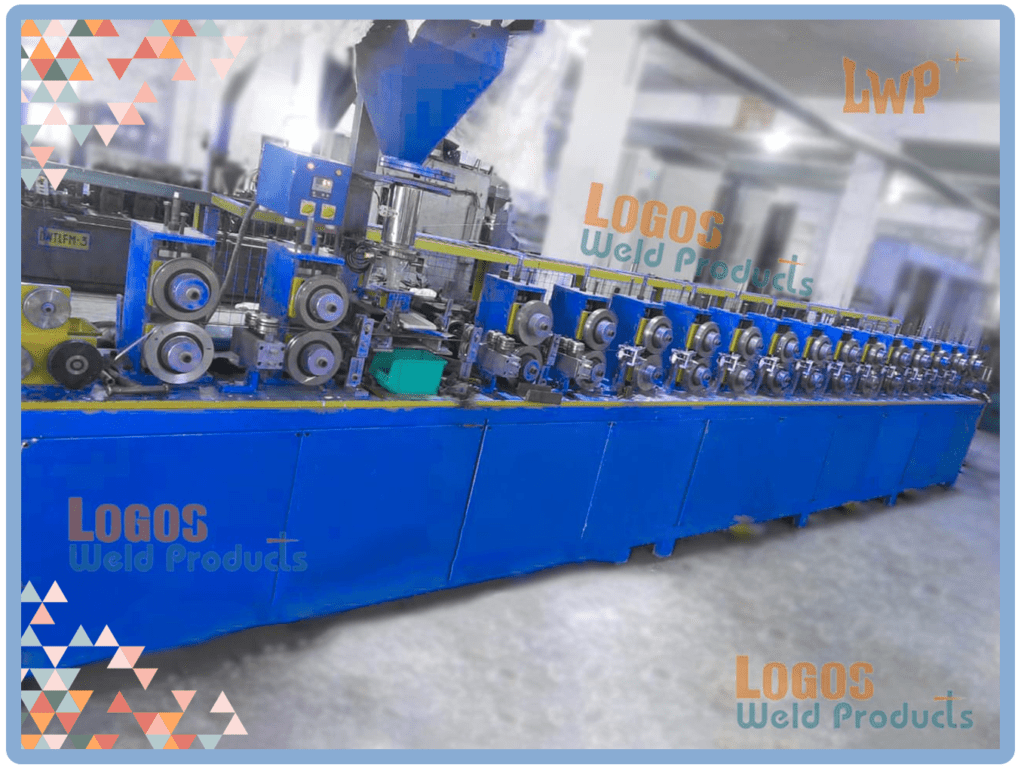

FLUX CORED WIRE MACHINE

BASIC TECHNICAL DETAILS AND LIST OF MACHINES FOR MANUFACTURING OF JOINING FLUX-CORED WIRE LIKE E 71T-1 (1.20MM)

| BASIC PARAMETERS AND METHOD | |

|---|---|

| The end diameter of Joining flux cored wire | 1.20mm |

| Strip Material | Low carbon Mild steel strip |

| Strip width | 12.00mm |

| Strip thickness | 0.80mm |

| FLUX FILLING RATIO | 12 TO 18% |

| Method of folding | BUTT |

| Production capacity | 2000 to 2500kgs per shift (12 HOURS). |

OUTLINE OF PRODUCTION PROCESS PLAN

We’ve innovatively designed a comprehensive line comprising 11 stations of a forming machine unit alongside a 3-head 600-diameter wire drawing and take-up unit. This integrated system efficiently processes strips through various stages at the forming station: cold bending, “U” forming, flux filling, and closure using the butt-type method. Following closure, the wire diameter undergoes reduction via forming rollers before advancing to the 3-head 600-diameter drawing and take-up unit, spooling the wire onto a bobbin. Subsequently, the wire transitions to the second line, featuring a 10-head 400-diameter drawing process meticulously tailored to achieve the desired finished wire size. Our Flux Cored Wire Machine technology expertise, spans as a Flux Cored Wire Machine manufacturer and Welding electrode flux exporter, ensuring precision and efficiency in welding electrode flux production.

LIST OF MACHINES

LINE-1

(FORMING UNIT WITH 3 Head drawing unit)

- Strip Pay off the unit to Forming unit (Dia 800 Bobbin)

- Online strip cleaning unit

| Forming Unit | |

|---|---|

| Total no of stations | 11 nos |

| Online flux filling unit | (700W servo motor with drive) Filling rate: 12-20%. |

| Take up unit. | (Dia 800 Bobbin) |

| Entire forming unit is operated by | touch screen and each roller speed Can be adjusted by VFD. |

| one set of Main rollers (150-160 mm dia) | one set of guide rollers will be supplied. |

Dia 600 -3 head drawing unit. The speed is automatically adjustable using sensors and VFDs.

Take up unit. (Dia 800 Bobbin) A touch screen operates the entire LINE-1. (HMI and PLC)

LINE – 2

(10 Head drawing unit-400 dia )-(2000 kgs/12 hours shift)

Wire pay-off unit. (Dia 800 bobbin)

Dia 400 -10 head drawing unit. The speed is automatically adjustable using sensors and VFDs.

Take up unit. ( Dia 630 Bobbin)

A touch screen operates the entire LINE -2. (HMI and PLC)

| The following machines are also required for production | |

|---|---|

| Flux mixing unit-1 no | 250 KGS/CHARGE |

| Flux Drying oven—1 no | 200 KGS /CHARGE |

| Strip and wire But welding machine | 3 nos |

| Stem Fixer | 1 no |

| DIN 800/630 Bobbins | 20 nos each |

| Oven for wire baking | 1 no-1000 TO 1500 KGS /CHARGE |

| Pointing machines | 2 nos |

| Strip Winding unit | 1 no |

| Shrink wrapping machine | 1 no |

| Vaccumm packing machine | 1 no |

| Weighing machine | 3 nos |

| Precision Layer winding Machine | 1no |

Flow Chart

WELDING ELECTRODE MACHINERY

- Dry Mixer

- Dry Mixer Double Cone Blender

- Wet Mixer

- Wire Straightening & Cutting Machine

- Briquetting Press/ Slug Press

- Wire Feeder Havelock with VFD

- Extruder Horizontal

- Extruder Vertical

- Conveyor With VFD

- Online Printing Unit

- Baking Oven Low & High Temperature

- Wet Flux Reclamation Machine

- Shrink Wrapping Machine Carton Box

- Wire Washing Machine

- Broaching Machine

- Wire Stripping Machine

- Wire Cleaning Machine

- Flux Sieving Machine

- Microscope

- Profile Projector

- flux Cored Wire Machine