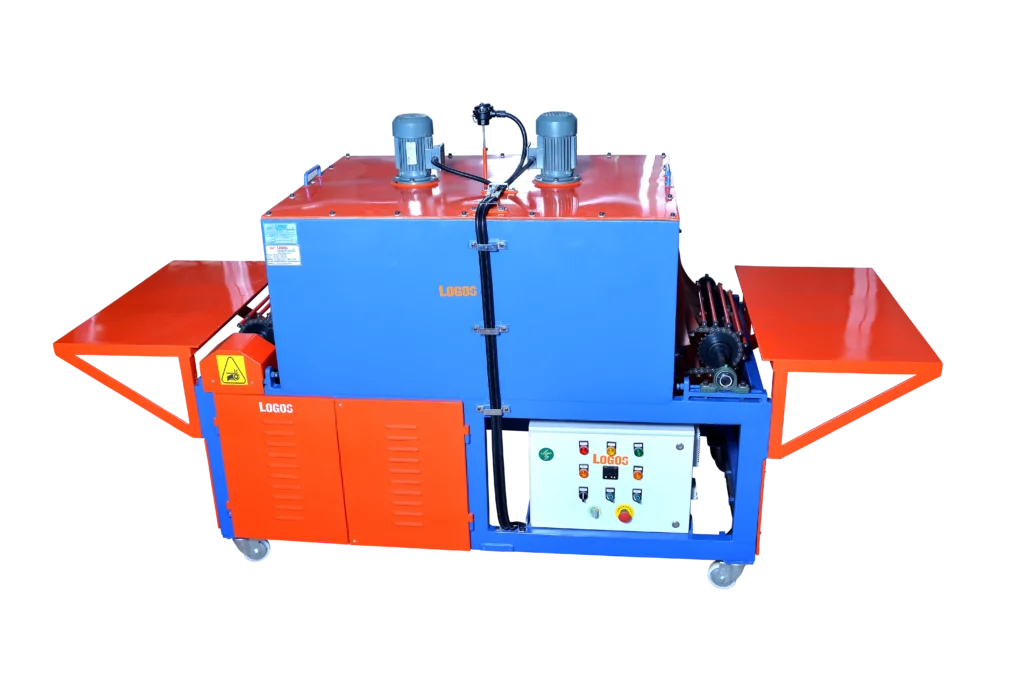

Shrink Wrapping Machine

Top-Quality Shrink Wrapping Machine from Logos Weld

A shrink wrapping machine is a pivotal component in the packaging industry. It utilizes heat to shrink a plastic film around a product, creating a tight, secure package. This technology offers a multitude of benefits, including product protection, enhanced presentation, and extended shelf life. For businesses looking to improve their packaging solutions, investing in a high-quality shrink wrapping machine is a must.

What is Shrink Wrapping

Shrink wrapping involves covering products with a plastic film and then applying heat. The heat causes the film to shrink tightly around the items, conforming to their shape and providing a secure, tamper-evident seal. This method is widely used in various industries, from food and beverages to electronics and pharmaceuticals.

Benefits of Shrink Wrapping

Shrink wrapping involves covering products with a plastic film and then applying heat. The heat causes the film to shrink tightly around the items, conforming to their shape and providing a secure, tamper-evident seal. This method is widely used in various industries, from food and beverages to electronics and pharmaceuticals.

Why Choose Logos Weld for Shrink Wrapping Machines?

Reputation and Expertise

Logos Weld Products, based in Coimbatore, is a renowned welding electrode manufacturing company that exports globally. With years of expertise in the industry, Logos Weld has established a strong reputation for delivering high-quality products and innovative solutions.

Commitment to Quality

Quality is at the core of Logos Weld’s philosophy. Their shrink wrapping machines are built using advanced technology and high-grade materials, ensuring durability, efficiency, and reliability. Every machine undergoes rigorous testing to meet international standards.

Customer Support

Logos Weld is committed to providing excellent customer service. They offer comprehensive support, from selecting the right machine to installation and maintenance. Their team of experts is always ready to assist with any queries or concerns, ensuring a seamless experience for their customers.

| DRY MIXER | |

|---|---|

| 2TON/SHIFT | 300KG |

| 3TON/SHIFT | 300KG |

| 5TON/SHIFT | 500KG |

| 8TON/SHIFT | 1000KG |

| 10TON/SHIFT | 1000KG |

WELDING ELECTRODE MACHINERY

- Dry Mixer

- Dry Mixer Double Cone Blender

- Wet Mixer

- Wire Straightening & Cutting Machine

- Briquetting Press/ Slug Press

- Wire Feeder Havelock with VFD

- Extruder Horizontal

- Extruder Vertical

- Conveyor With VFD

- Online Printing Unit

- Baking Oven Low & High Temperature

- Wet Flux Reclamation Machine

- Shrink Wrapping Machine Carton Box

- Wire Washing Machine

- Broaching Machine

- Wire Stripping Machine

- Wire Cleaning Machine

- Flux Sieving Machine

- Microscope

- Profile Projector

- flux Cored Wire Machine

How to Choose the Right Shrink Wrapping Machine

Assessing Your Needs

The first step in choosing the right shrink wrapping machine is to assess your packaging needs. Consider factors such as the type of products, production volume, and budget. This will help you determine the most suitable machine for your requirements.

Evaluating Features

When evaluating shrink wrapping machines, consider the features offered by different models. Look for machines with adjustable settings, user-friendly interfaces, and energy-efficient components. These features can significantly impact the machine's performance and ease of use.

Considering Maintenance and Support

Maintenance and support are crucial factors to consider when purchasing a shrink wrapping machine. Ensure that the manufacturer offers reliable customer support and maintenance services. This will help you keep the machine in optimal condition and address any issues promptly.

Maintenance Tips for Shrink Wrapping Machines

Regular Cleaning

Regular cleaning is essential to maintain the efficiency and longevity of your shrink wrapping machine. Remove any dust, debris, or residue from the machine components to prevent blockages and ensure smooth operation.

Routine Inspections

Conduct routine inspections to identify any signs of wear or damage. Check the heating elements, conveyor belts, and other critical parts for any issues. Early detection of problems can prevent costly repairs and downtime.

Professional Servicing

Schedule professional servicing at regular intervals to keep your machine in top condition. Trained technicians can perform thorough inspections, address any issues, and replace worn-out parts. This will help you maintain the machine's performance and extend its lifespan.

Market Trends

The demand for shrink wrapping machines is expected to grow in various industries, driven by the need for efficient and reliable packaging solutions. Logos Weld is well-positioned to meet this demand with their high-quality machines and commitment to customer satisfaction.

Logos Weld’s shrink wrapping machines offer top-quality packaging solutions. With their advanced technology, versatility, and commitment to quality, Logos Weld ensures that their machines meet the highest standards. Whether you are in the food, pharmaceutical, or electronics industry, Logos Weld has the perfect shrink wrapping machine to enhance your packaging process. Invest in a Logos Weld shrink wrapping machine today and experience the benefits of efficient, reliable, and professional packaging.