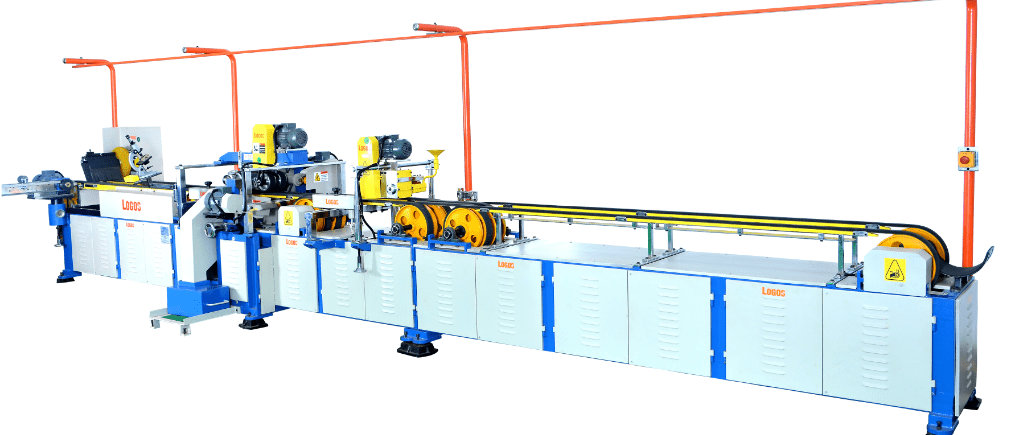

Welding electrode manufacturers in India, such as Logos Weld Products, are redefining industrial operations with advanced solutions designed to meet modern manufacturing demands. Among their most impactful innovations are conveyors equipped with Variable Frequency Drives (VFDs). These systems have become critical for streamlining production processes, improving energy efficiency, and delivering operational flexibility across industries.

Logos Weld Products, a globally renowned manufacturer and exporter based in India, offers state-of-the-art conveyor systems integrated with VFD technology. This article explores how these conveyors are revolutionizing manufacturing processes, detailing their features, benefits, and applications.

Advantages of Conveyors with VFD Technology

Unmatched Energy Efficiency

One of the standout benefits of VFD-equipped conveyors is their ability to optimize energy consumption. By adjusting motor speed based on load demand, these systems prevent energy wastage and reduce operating costs. For companies prioritizing sustainability, such as welding electrode manufacturers in India, this feature contributes to a smaller carbon footprint.

Enhanced Process Precision

The precise control offered by a VFD ensures smooth and consistent operation, even during complex tasks. Whether transporting delicate materials or heavy loads, the ability to regulate speed and torque minimizes material damage and ensures high-quality outcomes.

Boosted Operational Productivity

In fast-paced manufacturing environments, downtime can be costly. Conveyors with VFDs can adjust speeds dynamically to match production requirements, eliminating bottlenecks and maximizing throughput. This adaptability translates into higher productivity and efficiency.

Extended Equipment Lifespan

Unlike conventional systems, VFD-equipped conveyors use gradual acceleration and deceleration. This feature reduces mechanical stress on components, minimizing wear and tear. As a result, businesses benefit from reduced maintenance costs and longer equipment lifespans.

Versatility Across Industries

The flexibility of VFD technology makes it suitable for a variety of industrial applications. These conveyors can easily adapt to different operational demands, making them indispensable in sectors such as welding, automotive, food processing, and logistics.

How Conveyors with VFDs Are Revolutionizing Welding Electrode Manufacturing

For welding electrode manufacturers in India, like Logos Weld Products, conveyors with VFDs have proven to be a transformative addition. In electrode production, precision and consistency are critical. VFD-equipped conveyors streamline the handling of raw materials, ensuring even distribution and seamless transitions during manufacturing.

Additionally, these systems facilitate efficient packaging and storage processes, helping manufacturers maintain high output levels without compromising quality. The integration of VFD technology also aligns with the industry’s growing focus on automation and smart manufacturing practices.

Why Logos Weld Products Stands Out

Logos Weld Products has established itself as a leader in delivering innovative industrial solutions. With years of expertise in manufacturing and exporting globally, the company ensures that its products meet the highest standards of quality and performance. Their conveyors with VFDs are a testament to their commitment to excellence, offering unparalleled efficiency and reliability.

The company’s ability to customize its conveyor systems to suit the unique needs of clients sets it apart. Each solution is customized to specific industrial requirements, ensuring optimal functionality. Additionally, Logos Weld Products provides comprehensive support services, from installation to maintenance, ensuring smooth operations throughout the product’s lifecycle. With a strong focus on quality assurance and a global reach, the company consistently delivers progressive solutions that meet the evolving demands of industries worldwide.

Applications of Conveyors with VFD Technology

Conveyors with VFDs are versatile tools that find applications across various industries. In welding electrode manufacturing, these conveyors streamline material handling, ensuring precision and efficiency throughout the production process. Their ability to adapt to different load capacities and production rates makes them indispensable in this sector.

In other industries, such as pharmaceuticals and food processing, conveyors with VFDs ensure the safe and hygienic transport of sensitive items. In automotive manufacturing, they improve assembly line operations by optimizing speed and reducing downtime. Similarly, in logistics, these conveyors enable efficient sorting and transportation, making warehouse operations seamless and productive. Their flexibility and adaptability make them a valuable asset in modern industrial environments.

Conveyors with VFDs have emerged as a cornerstone of modern manufacturing, offering a blend of efficiency, precision, and adaptability. For welding electrode manufacturers in India, such as Logos Weld Products, these systems are indispensable for maintaining competitive production standards and addressing industry challenges.

Logos Weld Products continues to lead the way by providing advanced conveyor solutions with VFD technology, empowering industries to achieve operational excellence while minimizing costs and environmental impact.