Imagining an entire structure, whether it be a bridge or a factory, collapsing due to a single faulty weld is terrifying – and that is exactly the risk taken when electrode test procedures skip a single step. Quality inspectors, production supervisors, and welding technicians have no choice but to master electrode test procedures; it is their first line of defence in obtaining flawless welds. In manufacturing, overlooked or hidden flaws have the potential to cost thousands in repairs, or the cost of a safety incident. Let an electrode not go to waste.

Why Electrode Testing Is Important

With the potential to have hidden variables, every batch of electrodes contains a unique combination of variables such as moisture, cracks in the coating, and instabilities in the welding arc. When the electrode test is skipped, it is an open invitation to flaws such as cracks or porosity. Resulting in more scrap and more downtime due to unoperational machines. The smart teams catch flaws before they even reach the production floor. When was the last time a set of electrodes went through a complete quality check?

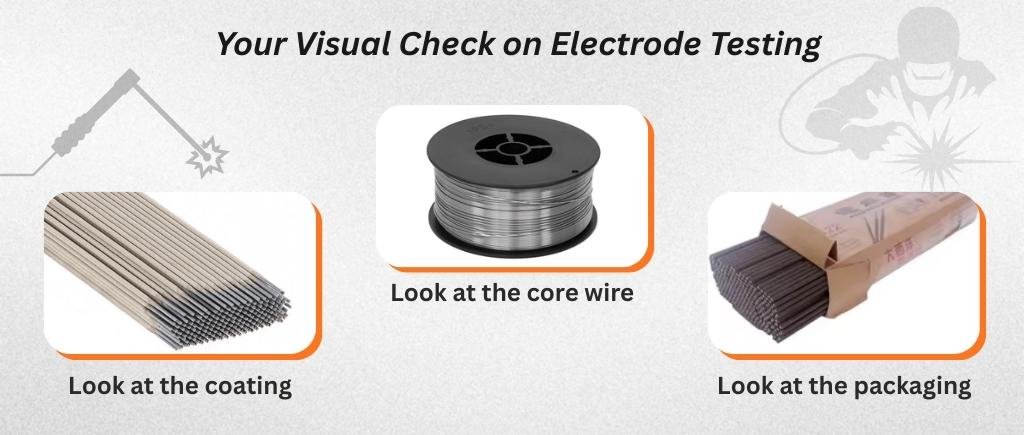

Your Visual Check

The first line of defence is unstriped rods.

- Look at the coating: It should be smooth and even. If there’s a coating it should be ready to weld rods. If it is chipped or cracked we should take it counsel.

- Look at the core wire: It should be straight and with no rust. If it is bent or discoloured it should be trashed, and it is trouble.

- Look at the packaging: we should check if it is opened too long. If it is moisture can sneak in fast.

Hands-On Arc Performance Test – How Does It Weld?

Fire up a test weld and see how properly set the arc is.

- Strike an arc and run a weld bead to fill the throat of a V-groove on a plate using the same material as the the job.

- Feedback loop: Stable arc? Good. Steady sound? Good. Smooth puddle? Good. No spatter? Good.

- Feedback loop: Popping sound? Bad electrode. Stop and rebake

Moisture Test for Low-Hydrogen Rods – No Exceptions

Low-hydrogen electrodes like E7018 don’t like moisture because of the cracks caused by the hydrogen that will kill the weld.

- Listen to the arc: Popping and spitting sounds mean there is moisture present.

- To fix this, rebake the rods by placing them in the oven set to 300 to 350 degrees for 1 to 2 hours.

- Store rods in an air tight container: so the electrodes will stay moisture free.

One damp rod in a weld joint can highly compromise the safety of an entire pressure vessel. Make sure to test every opened pack.

Bend and Impact Tests – Strength under Pressure

Cut test welds and obtain lab-grade proof of the passes and fails

- For the bend test: 180° fold the weld. No cracks? It passes toughness.

- Charpy V-notch: Hammer a notched sample and see how a lot of high energy is absorbed. This will mean the sample is ready for high energy impacts.

- Tensile pull: Stretch until break – target strength met?

These confirm your electrodes deliver on promises. Share in comments: What’s your go-to strength test?

Non-Destructive Checks – X-Ray and Beyond

No cutting needed for in-process wins:

- Radiography (X-ray): Spots internal voids or inclusions invisible to the eye.

- Magnetic particle: Reveals surface cracks with magnetic powder magic.

- Ultrasonic: Sound waves catch deep flaws fast.

Perfect for high-value jobs – pipes, boilers, structures. When do you pull these tools?

Storage and Handling – Test Your Systems Too

Bad storage fails even premium electrodes:

- Oven temperature: 250°F minimum, rods never over 9 hours out.

- FIFO rule: First in, first out – no ancient stock surprises.

- Humidity control: Under 60% RH or face hydrogen hell.

Audit your rack today – what’s lurking in the back?

Partner with Proven Experts for Testing Confidence

Mastering electrode test routines puts you in control of weld destiny. Catch flaws early, slash rework 50%, and deliver bulletproof quality your clients trust.

Ready to elevate? Connect with top Welding Electrode making machine Manufacturers and explore the complete Welding Electrode Plan – built for testing triumph and production perfection.