In 2025, automated welding production is rapidly transforming manufacturing floors worldwide. However, one critical challenge remains: bridging the skill gap among workers who must operate, monitor, and maintain these advanced systems. For plant managers, HR trainers, and welding supervisors, equipping the workforce with the right skills is the key to unlocking the full potential of automation, ensuring safety, efficiency, and long-term success.

Why Training for Automated Welding Production Matters Now

The move to automated welding lines means traditional skills shift toward new technologies, software, and hands-on interaction with robotic systems. Without targeted training, productivity stalls, errors rise, and costly downtime becomes common. Closing this gap enables your plant to thrive in Industry 4.0 and beyond.

-

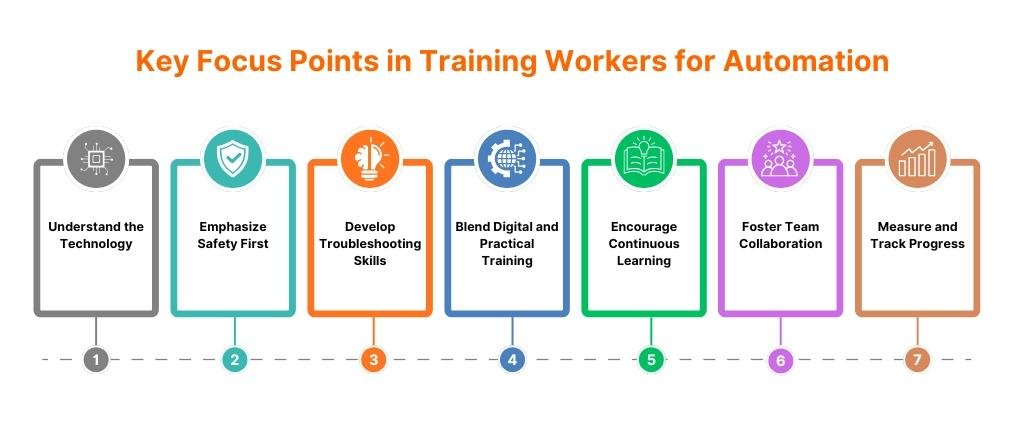

Understand the Technology

Workers must grasp fundamental operating concepts—including how robots function, sensor roles, and basic software controls. Simple, hands-on learning sessions with real equipment help build confidence and reduce anxiety around machines.

-

Emphasize Safety First

Automated welding involves high voltages, heat, and moving parts. Training programs should include clear safety protocols, emergency response drills, and use of personal protective equipment to protect workers while interacting with automated systems.

-

Develop Troubleshooting Skills

While automation reduces errors, technical glitches happen. Teaching workers basic troubleshooting, fault diagnosis, and preventive maintenance empowers them to quickly resolve issues and minimize downtime.

-

Blend Digital and Practical Training

Combine virtual simulations, e-learning modules, and on-floor practice. Interactive digital tools provide safe environments for mastering robotic controls before actual production, accelerating learning curves.

-

Encourage Continuous Learning

Automation technologies evolve fast. Establish programs for ongoing skills refreshers, new tech briefings, and cross-training to keep workers adaptable and future-ready.

-

Foster Team Collaboration

Automated welding is a team effort between operators, programmers, and maintenance staff. Training should promote communication, clarity in roles, and coordinated problem-solving to optimise line performance.

-

Measure and Track Progress

Use assessments, certifications, and performance tracking to ensure training effectiveness and identify areas for improvement. Recognise and reward achievements to motivate workers.

Engaging Training Tips

Effective training for automated welding production thrives on active engagement and real-world connection. Using real-world scenarios and case studies allows trainees to clearly see how their skills impact production outcomes, making lessons meaningful and relatable. Encouraging questions and hands-on trials during training sessions helps build confidence and reinforces learning by allowing workers to interact directly with the equipment and software. Gamifying learning with challenges and rewards introduces a fun, competitive element that motivates participants to improve their skills and stay focused. Finally, regularly inviting feedback ensures that training methods remain relevant and effective by addressing learners’ needs and continuously adapting content to maximise understanding and engagement.

Why it’s Critical for Your Business

Bridging the skill gap increases manufacturing efficiency, reduces operational risks, and improves employee satisfaction and retention. It also aligns your plant with global quality standards and innovation demands.

Unlock smoother production with tailored automation skill development and explore powerful solutions from leading Welding Electrode making machine Manufacturers can complement your workforce training, helping you fully leverage automated welding production.

Hello pals!

I came across a 146 fantastic tool that I think you should take a look at.

This platform is packed with a lot of useful information that you might find interesting.

It has everything you could possibly need, so be sure to give it a visit!

[url=https://officiallineageos.com/top-5-ways-to-get-out-of-a-career-dead-end/]https://officiallineageos.com/top-5-ways-to-get-out-of-a-career-dead-end/[/url]

Additionally remember not to overlook, folks, that one at all times may within this article discover solutions to address the most the very complicated queries. Our team attempted to explain the complete content via an most easy-to-grasp manner.

# Spintax Version:

Салют всем, кто думает о поездку в Калининград! Если вас беспокоит, можно ли окунаться в Калининграде летом, стоит знать, что температура моря в Балтийском море у coastal area Калининграда в августе традиционно достигает благоприятных 18-20 градусов, что помогает насладиться купальным сезоном на amber beach или Куршской косе. Зимой, понятно, море прохладное, и зимой температура в Калининграде часто держится около 0 градусов, однако город славится своей исключительной архитектурой, исторической частью и привлекательными улицами, а также органными концертами в кафедральном соборе.

Если вы хотите узнать глубже о том, куда заглянуть вечером в Калининграде или что изучить в Гвардейске и Светлогорске с чадами, настоятельно рекомендую посетить расположенные тут замки и форты, такие как, форт № 11 – Дёнхофф, а также экспозицию янтаря. Для подготовки маршрута и практичной информации можно заглянуть сюда [url=https://school16vlad.ru/]форты калининграда[/url] . Кроме того, в Калининграде достаточно уютных кафе с утренним меню, а также интересных мест для променада, включая зеленоградск и деревню рыбаков – замечательное место для досуга всей семьей.

Если собираетесь поездку в Калининград, непременно уделите внимание диким пляжам Калининградской области и купальному сезону в Балтийском море — здесь можно купаться уже с июня, несмотря на то что температура воды порой прохладная. Для прогулок превосходно подойдёт пеший маршрут по Калининграду с посещением старой части города, кафедрального собора и панорамных точек, а также стоит побывать в калининградский зоопарк — не забудьте проверить режим работы и цену билетов заранее. Более подробную информацию можно найти тут [url=https://superotvet.ru/]где купить янтарь в калининграде[/url] .

Дополнительно советую присмотреться на архитектуру Калининграда с примерами тевтонского стиля и форт Дёнхофф с его фото, которые идеально подойдут для фанатов истории. Для приятного путешествия узнайте, как достичь до популярных мест, например, в Зеленоградск на электричке или до Рыбной деревни. Если разыскиваете, где вкусно позавтракать в Калининграде, большое количество кафе предлагают великолепные завтраки — идеальный старт дня перед знакомством с достопримечательностей.