Have you ever thought about how some welding jobs turn out while others result in mishaps? The example lies in one powerful but simple step, the EQT test. If you are on a maintenance crew, in the position of a safety officer, or in the role of a machine operator, learning this test can save lives, avert costly machine failures, and keep your workplace free of disruptions. In the first few minutes of a shift on the welding machine, conducting an EQT test will undercut the likelihood of any surprises. Would you like to make safety your after?

Why EQT Test is Important for Every Coordinate

A scenario: A five minute check can save hours of work, and can avert serious injuries. The eqt test is on the front line when it comes to faulty test eqt test stands for Equipment Quality Test.

Identify issues: Inspect and report loose, worn, and frayed components and ruptured cables.

Self-assured: Safety increases as does the operator’s work rate when the equipment is of good quality.

Save money: Small problems can be fixed to avert serious costly repairs.

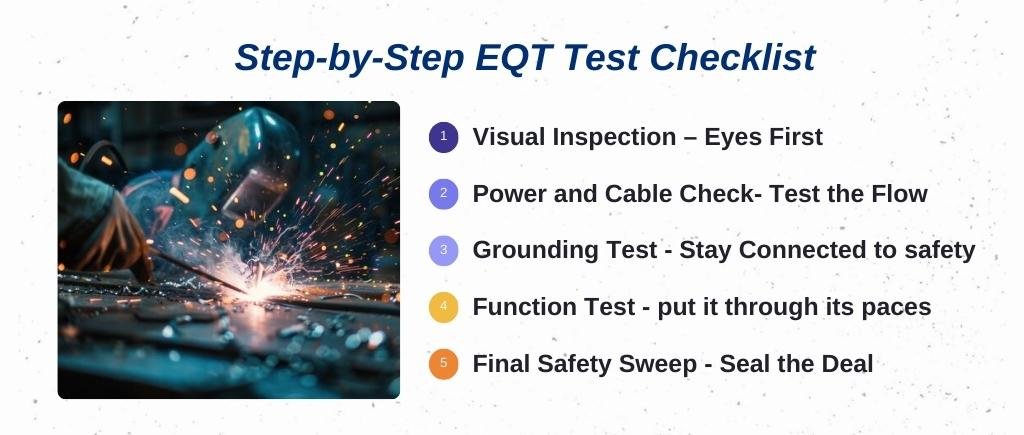

Step-by-Step EQT Test Checklist

It’s as easy as that. Get your equipment and let’s go!

-

Visual Inspection – Eyes First

- Commit your eyes to the look over every piece of welding equipment as though you are going to check a car for a long drive.

- Check for cracks, dents, or dents on the torch, cables, and holders.

- Make sure safety labels and stickers are present and readable.

- Remove dirt and oil that can hide potential issues.

-

Power and Cable Check- Test the Flow

- Safety and functionality begin with electricity acting how it should.

- Plug in and turn on. Does the power light turn on?

- Give the cable a tug. There shouldn’t be any frays, cuts, or exposed wires.

- After one minute feel the cable. Warm is good, hot means bad.

-

Grounding Test – Stay Connected to safety

- A good ground stops shocks.

- Use a multimeter to Measure grounding clips.

- Make sure there are clean and tight connections to the metal work piece.

- Continuity Test- Should be Zero ohms.

-

Function Test – put it through its paces.

- Time to see the machines do work (safely).

- Run a test weld on a piece of scrap metal.

- Watch the arc. It should be steady and not spitting or jumping.

- If you are using the MIG do a gas flow check. It should be smooth and steady.

-

Final Safety Sweep – Seal the Deal

- Check everything before you go full gas.

- Check that is on PPE. Helmets and shields are all in good shape?

- Make sure the area is clear of any flammable material.

- Record the test. Date. Time. Your initials for the records.

Mistakes to Avoid

- Visual check. Don’t rush it.

- Small sparks and weird smells. Don’t ignore them.

- The logbook. Records show your commitment to safety.

Ready to Level Up Your Safety Game?

When your maintenance team becomes safety champs by mastering the eqt test, production keeps flowing. It’s that easy, and it saves lives.

Need state-of-the-art equipment that aces every EQT test? Look at the leading Welding Electrode Making Machine Manufacturers and check our entire Welding Electrode Line for unparalleled dependability.