If you work around metal, machinery, or maintenance, you need to know about the different types of welding. It’s smart, safe, and necessary for most factory work. You’re aware of the different techniques to save money, make stronger and cleaner joints that don’t need to be redone, and that last a long time.

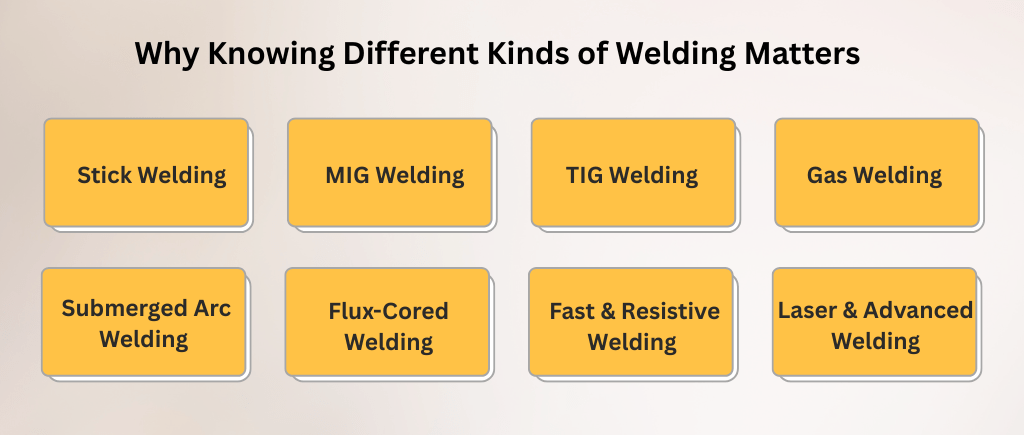

Why Knowing Different Kinds of Welding Matters

You won’t be cutting corners and being careless with welding thinner materials. Knowing the welding techniques differentiates pipe and repair work.

Different techniques improve different things such as safety and decreasing the chances of having a major failure since every technique has a different set of pros and cons.

- Stick Welding – The Tough All-Rounder

- Stick welding is best for working outdoors and is great for rusty and dirty metal as it uses a coated stick.

- It has many industrial uses, so it is essential for most industrial and maintenance jobs.

- MIG Welding – Fast and Easy to Learn

-

-

- 35765 M metal welding smooth and quickly on mild stainless steel, and aluminium. MIG uses continuously fed wire and shielding gas so a huge tip is working quickly.

- Because it’s simple to understand, helps consistency, works well with automation, and produces items in bulk, many factories opt to work with MIG in their production lines

</ul >

-

- TIG Welding – For Clean, Precise Work

- With TIG welding (Gas Tungsten Arc Welding), control of the weld pool is vastly improved thanks to the non-consumable tungsten electrodes and the separate filler rods.

- This welding method works best for high precision or good aesthetics-required jobs, like high-value components, thin sections, or food-grade equipment and stainless steel tanks.

-

- Flux-Cored Welding – High Productivity on Heavy Jobs

- Depending on the type of wire being used, Flux Cored Arc Welding works with or without external shielding gas using tubular wires with flux on the inside. High deposition rates and strong welds take priority over the appearance of the weld.

- This type of welding is well suited for its use in thick sections, and it’s popularity for being used on high fabrication and outdoor jobs.

-

- Submerged Arc Welding – Deep Welds, High Speed

- Out of all welding, Submerged Arc Welding most efficiently accomplishes long, straight welds. It’s also valuable for its speed and great depth of penetration, and works best on heavy plates like beams, large pipes, or pressure vessels.

- It feeds a bare wire under a blanket of granular flux, covering the arc and greatly reducing spatter and fumes.

-

- Gas Welding (Oxy-Fuel) – Usage for Repairs Keeping Old Methods

- Oxy-fuel welding is where you use a flame (usually oxy-fuel) to melt the base metal and adhesive instead of using electricity.

- It’s now mainly used for light repairs or sheet metal cutting, yet knowing about it gives workers experience for controlling heat and learning about pool behaviour.

-

- Fast and Resistive Welding – Fastening Sheets Together

- Spot and resistive welding are used when 2 pieces of metal are pressed together, and a current runs through the metal until they’re fused together.

- Factories that make cars or large home appliances use this method for fast and easy metal jointing that needs little to no additional metal to fill gaps.

-

- For Modern Factories – Laser and Advanced Welding

- Laser welding is used for a lot of modern parts and electronics, it focuses a beam of light to get very accurate welds that are narrow and slightly distorted, but still good.

- Factories use automation for laser welding and other fast and accurate processes that use robots and sensors.

-

Knowledge of Industrial Workers

-

-

- Overloading a single process for production is inefficient. Factory owners can assign each job to the optimal welding process to improve production.

- If there is a better understanding of welding and its various types and strengths, supervisors and welders can plan out training, safety equipment, and inspection techniques better.

-

To cater to these methods of welding with dependable welding consumables and equipment, a lot of plants maintain a solid Welding Electrode Plan and collaborate with Welding Electrode making machine Manufacturers like Logos Weld Products, making sure there is consistent quality from the production of the electrodes to the completed weld.

If you’re curious about finding your right color palette, applications like color analysis pro can be really helpful. For example, the deep summer color palette offers chilly, muted shades that perform wonderfully for those with a deep summer color season. If you ever make up your mind that the app isn’t for you, finding out how to cancel color analysis pro is direct, and many forums illustrate the process plainly to prevent confusion.

For a cost-free alternative, you can try an ai color analysis free tool online; these frequently offer fast insights into your skin tone and best seasonal colors, like soft autumn or light spring. If you’re currently wondering “what season am I?” there are plenty of quizzes and skin tone charts accessible that can lead you. You can begin exploring options here: [url=https://color-analysis-quiz.org]seasonal colors[/url] .

Если собираетесь поездку в Калининград, определенно загляните в Рыбную деревню — это крайне колоритных мест города с великолепными видами и приятными ресторанами. В этом месте можно отведать свежей рыбой и погулять по живописным улицам старого города, не забывая про кафедральный собор Святых Петра и Павла с его известным органом, где систематически проходят органные концерты. Для энтузиастов природы стоит посетить остров Канта и первозданные пляжи Калининградской области, а также пройти маршрут по району Амалиенау.

Что говорит о моря, то в Калининграде омывается Балтийским морем — окунаться в нём летом довольно можно, несмотря на то что вода изрядно прохладная. Если интересует температура воды или погода зимой, лучше посмотреть полный гайд [url=https://centr-zamaniya.ru/]куда сходить в калининграде вечером[/url] , где есть новая информация и подсказки по маршрутам, электричке Калининград–Зеленоградск, а также достопримечательностям Правдинска и Черняховска. Отличного отдыха и насыщенных впечатлений!

Если вы планируете поездку в Калининград и размышляете, какое море омывает этот населённый пункт, то это, конечно, Балтийское море. Многие туристы задаются вопросом, можно ли принимать морские ванны в Балтийском море в Калининграде — водный сезон здесь краткий, вода достаточно прохладная, особенно в начале лета. Оптимальное время для прибрежного отдыха — июль и август, когда температура воды приближается к комфортных отметок. Подробнее о температуре воды и погодных условиях в Калининграде можно узнать на специализированных сайтах [url=https://kolyaska-indigo.ru/]температура воды в калининграде[/url] .

Наряду с моря, обязательно съездите в знаменитый Танцующий лес и Калининградский зоологический парк — билеты туда сейчас без труда купить онлайн. Не забудьте наведаться на остров Канту и прогуляться по району Амалиенау, его пешие тропы отлично созданы для самостоятельных прогулок. Почитателям органной музыки предлагаю органный концерт в кафедральном храме — здесь размещён самый большой орган в России, и атмосфера просто потрясающая. Вечером можно посетить в рыбную деревню или заехать на концерт в органный зал — позитива хватит надолго!

Если вы планируете поездку в Калининград, необходимо знать, что балтийское море в этом регионе прохладное — температура моря в Калининграде летом нечасто поднимается выше +18…+20°C. Сезон купания обычно берет начало в июне и продолжается до августа, но возможно ли купаться в Калининграде в сентябре или октябре, дело ваше — вода моментально остывает. Для тех, кто увлекается достопримечательностями, советуем обратить внимание на средневековые замки Калининградской области, форт 11 Калининград и старую часть с красивыми улицами и архитектурой.

Если решите провести вечер в Калининграде, рекомендуется заглянуть в зал органной музыки, где еженедельно проходят концерты органной музыки, а для тех, кто с детьми прекрасно подойдут музеи и зоопарк. Добавим, если хотите найти, куда сходить в Светлогорске с детьми или куда направиться в Гвардейске — там аналогично множество интересных мест и природных красот. Полный маршрут и актуальные советы по погоде и экскурсиям увидите здесь: [url=https://school16vlad.ru/]где самый большой орган в россии[/url] .

Если вы планируете поездку на Тенерифе, непременно стоит посетить Monkey Park Tenerife и культовое драконовое дерево — символ Канарских островов. Также рекомендую обратить внимание на пляжи, например, пляж Тереситас и бассейны Lago Martianez, где отлично можно отдохнуть и любоваться природой. Для маршрутов по острову удобно использовать bus Tenerife, расписание которого легко найти в интернете, например, план ligne de bus Tenerife.

Помимо Тенерифе, на Канарских островах масса интересного: Лансароте, Ла Пальма и Фуэртевентура с их исключительной природой и достопримечательностями. Если вас манит карнавал, то carnival Tenerife 2025 обещает быть зрелищным событием. Данные и актуальные советы по поездке по островам и другим городам Испании можно узнать здесь [url=https://hotelsspain.ru/]херес де ла фронтера[/url] .

Your writing always inspires me to learn more.

I wish I had read this sooner!

I always look forward to your posts. Keep it coming!

Если задумали тур по Испании, несомненно взгляните на указанные места, как путь Святого Иакова (Camino de Santiago), саграда Фамилия в Барселоне и вулкан Тейде на Тенерифе на карте. Для фанатов моря замечательным выбором будут курорты Коста Дорада, Коста Бравы и Канарские острова, например Лансароте, Ла Пальма и Фуэртевентура. В дополнение к моря в Испании, следует исследовать исторические места и архитектуру населенных пунктов, как Мадрид (центр точно понравится музеем Прадо) и Севилья с её Алькасаром.

Если вам интересно, где находится Ибица и другие острова Испании, легко быстро отыскать свежую информацию на сайте [url=https://spanishinspain.ru/]тенерифы[/url] . К тому же не оставляйте без внимания о курортах Аликанте, Кальпе и Салоу, где есть великолепные пляжи и развлечения. Почитателям творчества и культуры понравятся музеи Дали в Фигерасе, а природолюбам — прогулки по Сьерра-Невада и парку Бандама на острове Гран-Канария. Учтите, что для покупки недвижимости или переезда в Испанию важно исследовать вопросы гражданства и местного законодательства.