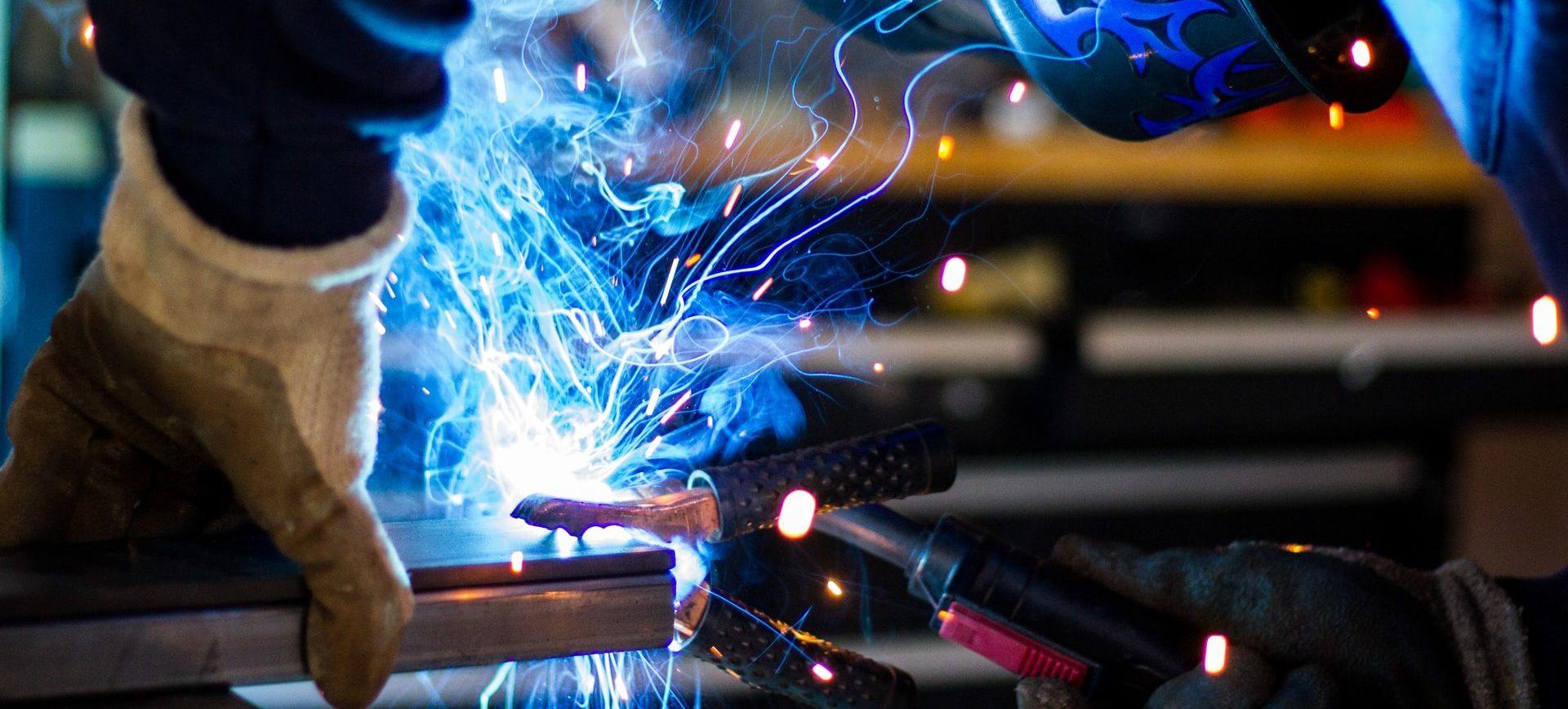

Electric Welding (or) Arc Welding

The electric Welding Process works in the Principle of converting the electrical energy obtained from the power source is converted to heat energy. This type of welding is also called Arc Welding. This type of welding process uses an electric arc produced from the power source to create heat energy to melt and join Metals. The electrodes used in this process use either Direct current or Alternating current.

This type of welding process is started in the late 19th Century. It became commercially popular during the ship-building process during the Second World War.

Types of Electric Welding Process

Electric Welding is classified into two types Electric Arc Welding and Electric Resistance Welding.

Electric Arc Welding

This type of welding is the most common method of Welding. This type of welding is also known as the Fusion welding Process. The Basic Principle behind this process is by the welding Heat obtained from the power source is formed as an electric arc formed between the welding electrode and the Welding Machines. This may be subdivided into many categories such as Mettalic Arc welding, Carbon Arc Welding, Atomic Hydrogen Arc Welding, Tungsten Inert Gas Arc Welding, Gas Metal Arc Welding, Submerged Arc Welding, and Plasma Arc Welding.

Electric Resistance Welding

It is a pressure-welding process in which the heat is obtained by passing a heavy momentary electric current through the inherent electric resistance of the joint to be welded. When the joint reaches a plastic state,

sufficient pressure is applied to produce fusion and get a homogeneous weld.

Welding Transformers

Welding transformer essentially steps down the voltage & for this reason, the output is low voltage excessive cutting-edge AC delivers. As the output is AC, it has a sinusoidal waveform. Due to its layout, it has quite a few circuit energy losses like hysterical losses. Thus a welding transformer operates at low efficiency & for this reason has a low energy factor.

Disadvantages of welding with transformer energy reasserts are that with the sinusoidal wave output the cutting-edge crosses the 0 mark two times in a cycle because of this the arc distinguishes one hundred instances a second. This produces excessive weld spatter. There is excessive height to height cutting-edge version which reasons a volatile arc. The device consumes excessive energy for the duration of welding & additionally while the device is ON. The device could be very cost-efficient for capital funding however the strolling charges are very excessive. For MMAW & TIG welding procedures steady cutting-edge (CC Type) welding transformers are designed. These are to be had in air-cooled & oil-cooled versions. The machines also are to be had in unmarried segment & 3 segment fashions from several 150A-600A. Welding transformers also are to be had for aluminum TIG welding because it gives AC output.

These transformers are utilized by small-time fabricators & additionally via way of means of system industries in which welding is finished for protection purposes. However, these days rectifiers & inverters are changing the transformers.

Welding Rectifiers

Welding rectifier offers a DC output via way of means of rectifying the low voltage excessive cutting-edge AC output received from the step-down transformer. The output is DC which has a ripple within side the DC waveform. With the development in transformer layout & PCB circuit controls, the rectifier ought to provide a progressed welding excellent & higher electrical efficiency.

Rectifiers provide a greater solid arc & the spatter is appreciably low. Even eleven though it has a DC output, the AC content material of the sinusoidal wave is imposed within side the output as ripples. However, the reaction time is slow & the output is depending on the entered variations. The device consumes excessive energy because of its mild efficiency & energy factor.

Welding Generators

Welding generator grants a natural DC output having no ripple content material which produces the maximum solid welding arcs appropriate for the MMAW system. The device layout produces a step-down voltage with a natural DC output. Generators provide a totally solid arc & the spatter is appreciably low.

Welding Invertors

Welding inverters are a boon to the welding industry. The era offers great excellent of welding, beginning to new welding procedures, energy-efficient, mild weight, etc.

The three-segment AC enter delivery is inverted to DC via way of means of a rectifier. This excessive voltage DC is transformed to excessive frequency AC (HFAC) via way of means of a transistor switching device. HFAC is stepped down via way of means of a transformer & inverted once more via way of means of a rectifier to get a DC output.

A 50Hz AC delivers while rectified will produce excessive ripple content material within side the resultant DC, while an excessive frequency AC at 20 kHz and above will produce a directly line DC output, HFAC is produced via way of means of IGBT (Isolated Gate Bipolar Transistor) or MOSFET (Metal Oxide Semiconductor Field Effect Transistor) kind of switching devices.