Have you ever thought about how a simple spark can magically fuse metal? Electric arc welding is a straightforward process. It’s used to create strong and dependable welds in factories, workshops, and garages. If you are a welding novice, factory trainee, or a DIY welder, this guide will give an explanation step by step, without using complex terminology. By the end, you will understand how this electric arc welding principle is used to repair almost everything, from bicycles to massive structures like bridges. Are you excited to learn?

The Electric Arc Welding Theory: Quick Start Hook

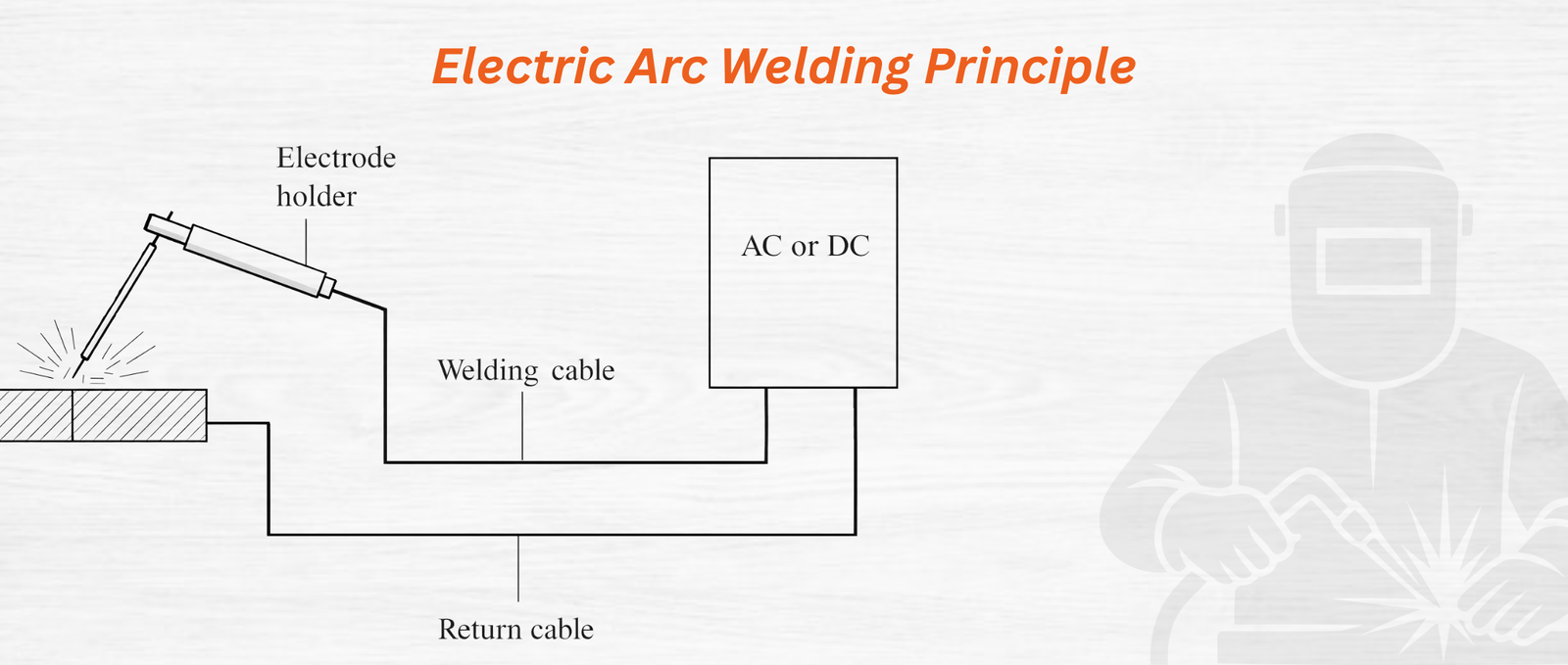

Picture electricity as a lightning bolt that jumps from one point to another. That is how electric arc welding works. A welding power source activates a current in the electrode (metal stick) being used to weld the metal. If the tip of the electrode gets too close to the metal workpiece, an arc is created, which is extremely hot, way hotter than the surface of the sun. It is hot enough to melt the metal pieces being welded and create a permanent bond. Simple, right? Let’s go deeper.

Step by Step: How It All Works

- Let’s start with a welding machine (power source), an electrode, and the pieces of metal you want to join. Attach the ground wire to your workpiece. Consider this ground wire to be the “return path” for the electricity.

- Hitting the arc: Hold the electrode as if it were a pencil and position it an eighth of an inch away from the workpiece. Scratch it lightly and zap! An arc will form. Pro tip: Practice on scrap metal—first try might be a dud, but it should work soon enough.

- Melt and Fuse: The arc’s heat will melt the electrode’s tip, and the base metal will form a molten metal puddle. Continue moving the puddle and it will solidify into a bead of metal. You can add filler material and increase the puddle’s size from the electrode if you want, it’s just like putting icing on a cake.

- Control the Heat: If the arc is too close, it will dig too deep, creating holes. If it’s too far, it will weaken. A steady “frying bacon” sound is perfect. What welding scares you the most? Tell us in the comments!

Why This Principle Wins Every Time

- Super Strong Joints: Welds can bond even stronger than the base metal. This is perfect for gates, frames or tools.

- Any, thin, thick, or anything in between. An affordable welding machine lets you do the job. Fun fact: This is the same technique that the Eiffel Tower was built with!

- Clear your space–make sure there are no flammable materials nearby.

Beginner Wins & Fixes

- Arc does not start?

Quick Fix: Clean the tip of the electrode and make sure all connections are tight.

- Is the puddle too big?

Quick Fix: Pull the electrode back and slow your travel speed.

- Weak spots in your weld?

Quick Fix: Make smooth and steady lines and always clean your metals (be sure to remove any rust or paint!).

- Is spatter everywhere?

Quick Fix: Angle your electrode about 10–15 degrees and keep your hand steady.

Upgrade Your Skills

If you learn the principles of electric arc welding and practice enough, you’ll develop a valuable skill you can use for the rest of your life. Try different electrodes to see which ones give you the smoothest arcs or the strongest welds. Find free instructional videos online, sign up for a local class, or challenge a friend to a welding competition.

Aren’t you ready to start making high-quality electrodes? Contact top manufacturers Welding Electrode making machine Manufacturers to help you achieve professional production.