Introduction

In various industries, the quality and cleanliness of wires are essential for seamless operations. From manufacturing to electrical applications, the presence of contaminants on wires can lead to performance issues and even safety concerns. In this blog post, we will explore the importance of wire washing machines and how they play a vital role in ensuring sparkling, clean wires for efficient and trouble-free processes.

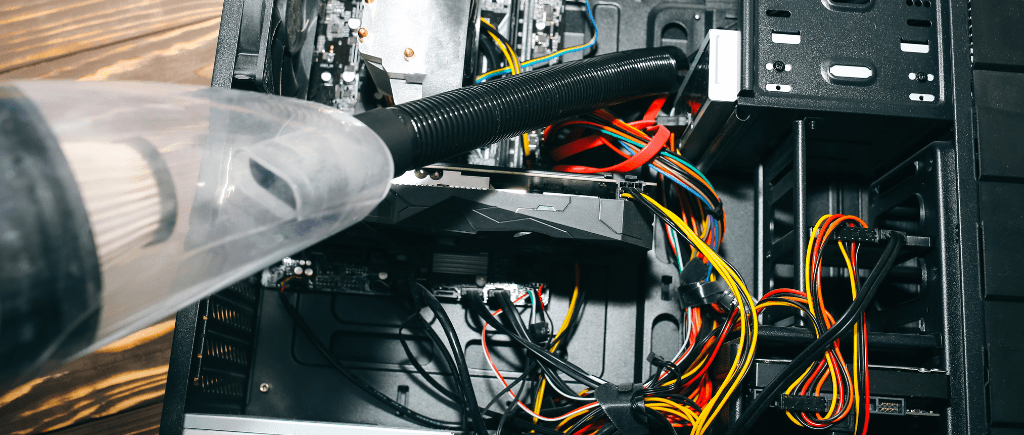

Understanding the Need for Clean Wires

Contaminated wires can lead to several problems, including reduced electrical conductivity, poor soldering, increased friction, and overall system inefficiency. In industries such as automotive, electronics, and aerospace, the quality of wires is critical. Clean wires are the backbone of reliable and high-performance systems.

The Role of Wire Washing Machines

Wire washing machines are specialized equipment designed to remove contaminants, oils, dust, and other unwanted substances from wires. These machines employ a combination of mechanical agitation, chemical cleaning agents, and high-pressure rinsing to achieve impeccable wire cleanliness. They can be customized to suit various wire types and sizes, making them a versatile solution for different industries.

Benefits of Wire Washing Machines

Improved Performance

Clean wires ensure optimal electrical conductivity and reduced resistance, leading to improved system performance and energy efficiency.

Enhanced Safety

In industries where wires are exposed to high temperatures, clean wires are less likely to catch fire or produce harmful fumes due to contaminants

Cost Efficiency

Reduced maintenance, fewer replacements, and increased lifespan of wires contribute to cost savings in the long run.

Environmentally Friendly

Many wire washing machines are designed to be eco-friendly, utilizing efficient water and chemical usage while minimizing waste.

Applications Across Industries

Automotive

Clean wires are crucial for various automotive applications, from wiring harnesses to sensors, where reliability is paramount.

Electronics

In the electronics industry, clean wires are essential for soldering, ensuring the longevity and functionality of electronic components.

Aerospace

In aerospace applications, clean wires are vital for safety and reliability, as they are used in critical systems and wiring harnesses.

Manufacturing

Clean wires play a pivotal role in Manufacturing, especially in industries that rely on precision and high-quality products.

Choosing the Right Wire Washing Machine

Selecting the appropriate wire washing machine for your specific needs is essential. Consider factors such as the type and size of wires, the level of contaminants, and the required throughput. Work with manufacturers or suppliers who can offer tailored solutions and provide ongoing support and maintenance.

Conclusion

Wire washing machines are unsung heroes in various industries, ensuring that wires are free from contaminants and ready to deliver exceptional performance. They not only enhance the efficiency and safety of operations but also contribute to cost savings and sustainability. By recognizing the importance of clean wires and investing in the right wire washing equipment, industries can maintain seamless and reliable processes while achieving sparkling results.