In this report, we will explore the project in terms of welding electrode manufacturing, as well as its related factors and necessary conditions for implementation.

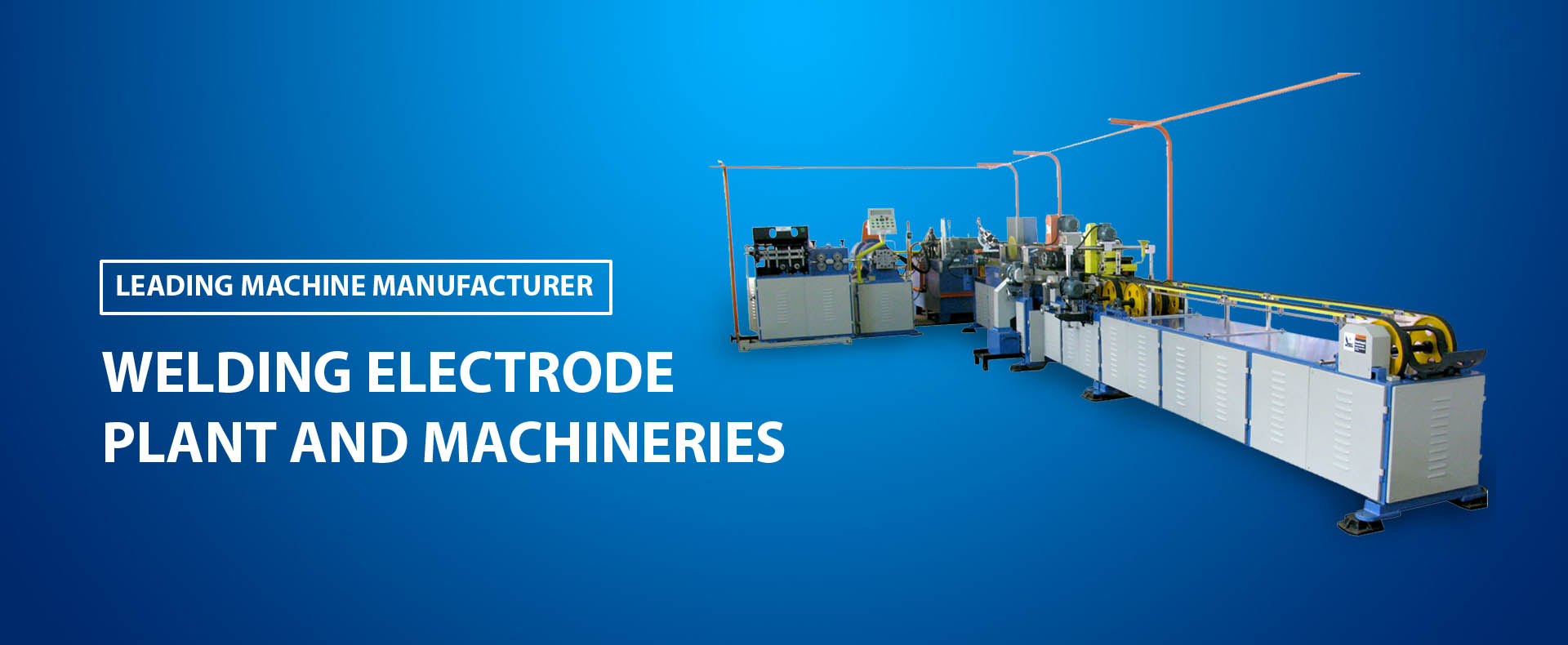

Welding Electrode Manufacturing Plant Introduction

Welding electrode manufacturing plant is a kind of new and advanced welding equipment. It has the features of high production efficiency, small size, low labor cost and good quality. In this paper, we will introduce the welding electrode manufacturing plant project report.

1) Project Introduction

This welding electrode manufacturing plant project is a kind of new and advanced welding equipment. The main purpose of this Welding Electrode Manufacturing Plant is to improve the welding process efficiency, reduce the labor cost and improve the quality of welding products. It has been designed with automatic control system and various types of automatic equipments.

2) Project Description

The Welding Electrode Manufacturing Plant consists of the following parts: an arc welder, a filler wire feeding system, a melting furnace, a quench tank, a cleaning system, and other machines and equipments. The arc welder can weld steel plate or other metals with an all-electric arc. The filler wire feeding system can feed various kinds of filler wires into the arc welder to produce various types of welds. The melting furnace melts the metal to be melted with heat. The quench tank cools down the melted metal so that it can be shaped into weld

Project Background

The welding electrode manufacturing plant project is a new investment for the company. It will provide them with a much needed increase in production, as well as providing much-needed jobs in the area. The plant will consist of three main sections: an arc welding machine section, a welder training section, and a production section.

The arc welding machine section will consist of five welders who will be able to weld using an arc welder. The welder training section will provide training for the welders in the use of the arc welder, as well as safety training. The production section will contain the five welders and the arc welder, and will be able to produce 900 welds per hour.

Project Goals

The goal of this welding electrode manufacturing plant project is to produce high-quality welding electrodes at a cost-effective rate. To achieve this, the project team will need to create a manufacturing process that is efficient and reliable. Additionally, the project team will need to develop efficient production methods and quality assurance procedures to ensure that the finished products are of the highest quality.

Work Breakdown Structure

The welding electrode manufacturing plant project is a new development by the company. The project will consist of the construction of a new welding electrode manufacturing plant. The plant will be located in a remote area and will require a substantial amount of investment. The project is expected to generate significant revenues for the company.

The work breakdown structure for the welding electrode manufacturing plant project is shown below. The project will consist of the following stages:

1) Design and engineering of the welding electrode manufacturing plant

2) Construction of the welding electrode manufacturing plant

3) Operation and maintenance of the welding electrode manufacturing plant

Scope Definition

The welding electrode manufacturing plant project report is a comprehensive document that provides information on the proposed project. The document includes a description of the proposed plant and its layout, as well as the types and quantities of materials that will be needed for its construction. Additionally, the report includes a detailed cost estimate for both the initial construction phase and the ongoing operational costs of the plant. The report also provides an analysis of the market potential for the proposed plant, as well as an assessment of any potential challenges that might be encountered during its construction.

Site Selection

The welding electrode manufacturing plant project will require a large site with ample space for the necessary equipment and support buildings. The site should be located in an area with good transportation and access to raw materials and other necessary supplies. The site should also have a stable, climate-controlled environment.

The Welding Electrode Manufacturing Plant Project team will need to consider several factors when selecting a site for the plant, including the following:

– Space Requirements: The plant will require a large amount of space, both for the manufacturing equipment and for the storage of finished products. The team will need to estimate how much space the plant will need and make sure that the site can accommodate that amount.

– Transportation: The site must have good transportation access so that deliveries of raw materials and finished products can be made easily. The team should also consider whether there is any nearby railroad or highway that could be used as a shipping route.

– Environment: The team will need to ensure that the site has a stable and climate-controlled environment. This includes assessing factors like wind speed, rain fall, and humidity levels.

Land Acquisition

A welding electrode manufacturing plant project report is hereby submitted. The proposed welding electrode manufacturing plant will be located in a rural area of the United States. The land acquisition process was conducted using a combination of negotiation, deed signing and bidding. The site selection process involved analyzing the facility’s location, surrounding environment, infrastructure and utilities availability.

The proposed welding electrode manufacturing plant will consist of the following facilities: a production line for producing aluminum welding electrodes, a storage facility for storing the electrodes, and a packaging facility to package the electrodes. The production line will use an extrusion process to produce welders from an alloy of aluminum and magnesium. The storage facility will store the welders in various shapes and sizes so that they can be easily transported to the production line. The packaging facility will package each welders into individual boxes.

Environmental Analysis

The environmental analysis of the welding electrode manufacturing plant project included a review of the potential environmental impacts of the project. The study looked at emissions from the plant, as well as water usage and waste generation. The study also examined ways to minimize environmental impacts.

Preliminary Design and Development

Welding electrode manufacturing plant project report covers the following: preliminary design and development, welding electrode manufacturing plant layout and equipment, process engineering, manufacturing techniques, quality control, and cost analysis.

Detailed Design and Construction Recommendation

The welding electrode manufacturing plant project is a $15 million investment by a major steel company and they are looking for a contractor to design and construct the plant. The contractor will be responsible for all the engineering, permitting, construction, and maintenance of the plant. They will also be responsible for providing quality control services for the plant.

The contractor will need to consult with the steel company to ensure that they are getting the best possible product. The contractor should also make sure that the plant is in compliance with all safety regulations. The contractor should also keep track of any changes in industry standards so that they can update their plans as needed.

Future Considerations

When welding electrode manufacturing plants, it is important to consider the future implications of the project. Here are a few considerations to keep in mind:

Environmental impact:

The manufacture of welding electrodes can have a significant environmental impact. In order to produce the electrodes using environmentally friendly methods, it is important to take into account the environmental factors that will be affected by the project. For example, what kind of waste will be created? What kind of air pollution will be created? How will the production process impact local wildlife?

Economic implications:

The manufacture of welding electrodes can have a significant economic impact. This is especially true if the plant is located in a region where there is already a high demand for welding electrodes. In order to ensure that the project has the best chance of success, it is important to carefully consider all of the economic factors involved in the project.

Safety implications:

The manufacture of welding electrodes can be dangerous work. That’s why it’s important to take into account safety issues when planning a welding electrode manufacturing plant. For example, will there be enough safety equipment available? How will accidents be handled? Will workers be properly trained in how to use the equipment? We will answer for these multiple questions to the coming up articles..

Conclusion

Based on the Welding Electrode Manufacturing Plant Project Report, the plant would be able to produce electrodes for use in welding and other metalworking. The plant would require a lot of initial investment, but it would be worth it in the long run since it would save customers money. It is also important to note that this is just a preliminary report, so more research will be needed before a final decision can be made.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/bn/register-person?ref=UM6SMJM3

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/it/join?ref=S5H7X3LP

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/register?ref=IHJUI7TF

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.info/uk-UA/register?ref=XZNNWTW7