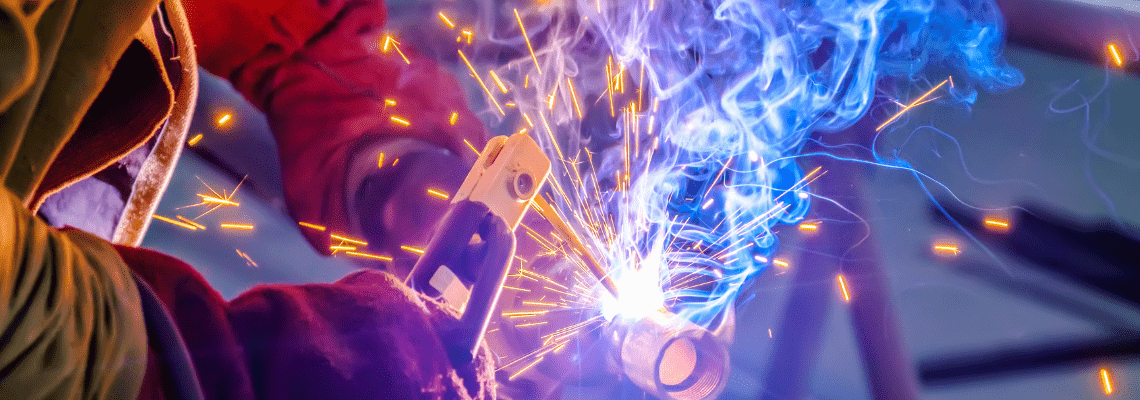

Welding, the craft of fusing metals to create structures of strength and durability, relies on a critical component: the flux cored wire. At the heart of producing these essential wires lies a sophisticated process, led by flux cored wire machine manufacturers. In this article, we delve into the world of these manufacturers, exploring their vital role in shaping the welding industry.

The Significance of Flux Cored Wire

Before diving into the world of manufacturers, let’s understand the significance of flux cored wires in welding. Flux cored wires are tubular electrodes filled with flux materials. When used in welding, they offer several advantages over solid wire electrodes, including higher deposition rates, increased efficiency, and greater flexibility in various welding positions.

The Crucial Role of Flux Cored Wire Machine Manufacturers

Behind every successful flux cored wire used in welding, there is a meticulous manufacturing process. This process is spearheaded by flux cored wire machine manufacturers who are dedicated to producing high-quality wires that meet the demands of various industries.

1.Wire Extrusion

The journey of a flux cored wire begins with the extrusion process. Raw materials, typically steel, are carefully selected and fed into specialized machines. These machines then extrude the steel into the desired wire diameter, ensuring precision and consistency. Flux materials are simultaneously introduced, creating the core of the flux cored wire.

2. Flux Mixing and Control

The quality of the flux mixture is paramount. Flux materials are blended to exacting specifications to achieve the desired chemical composition. Manufacturers employ sophisticated equipment to ensure precise mixing, controlling factors such as particle size and distribution. This meticulous approach results in flux cored wires with superior welding properties.

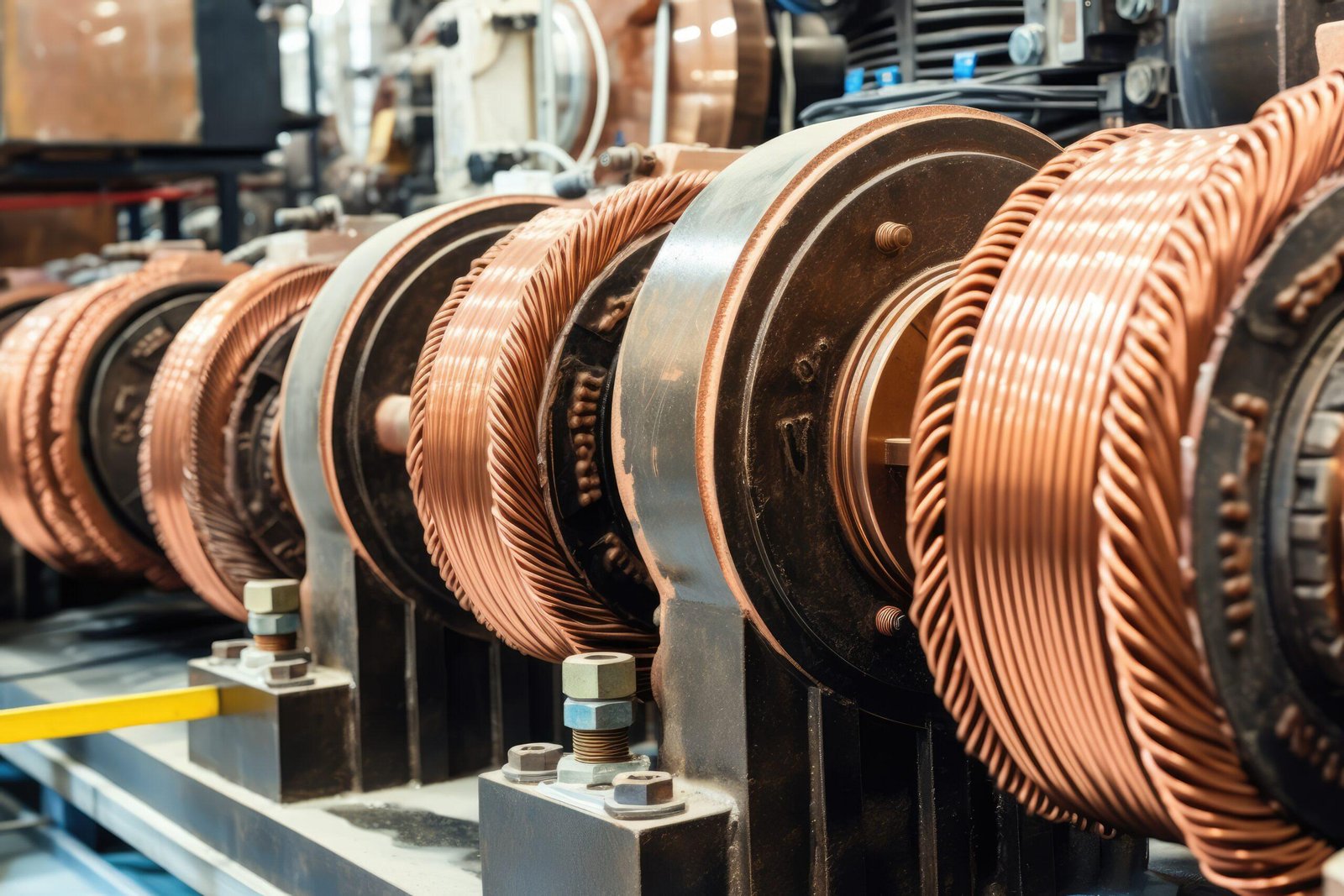

3. Continuous Welding Machines

Once the flux core is prepared, it is time for the wire to be sheathed with a metal cover. Continuous welding machines are employed for this purpose. These machines wrap the flux core with a precisely controlled metal sheath. The choice of sheathing material can significantly influence the wire’s performance, making this step crucial.

4.Quality Control

Stringent quality control measures are implemented at every stage of the manufacturing process. Flux cored wires are subjected to tests for tensile strength, chemical composition, and diameter consistency. Manufacturers adhere to industry standards and certifications to guarantee the reliability of their products.

5.Packaging and Distribution

After passing rigorous quality tests, flux cored wires are spooled onto reels or coils using specialized winding machinery. These products are then carefully packaged and prepared for distribution. Packaging is designed to protect the wires from damage and maintain their integrity during transportation and storage.

Choosing the Right Manufacturer

Selecting the right flux cored wire machine manufacturer is pivotal for welders and industries that rely on quality welding materials. Here are some key considerations:

Quality Standards

Ensure the manufacturer adheres to industry standards and certifications, guaranteeing the reliability of their products.

Innovation

Look for manufacturers that invest in research and development to create wires with improved welding properties.

Customization

Some projects require specialized flux cored wires. Choose a manufacturer capable of producing customized solutions.

Environmental Responsibility

In today’s world, sustainable manufacturing practices are crucial. Consider manufacturers committed to environmental responsibility.

Customer Support

Manufacturers that offer comprehensive customer support can be invaluable when technical guidance or assistance is needed.

Conclusion

Flux cored wire machine manufacturers are the unsung heroes of the welding industry, shaping the materials that welders rely on for their craft. Their commitment to quality, innovation, and precision ensures that welding projects, from small repairs to massive infrastructure undertakings, are executed with excellence. When selecting a manufacturer, welders and industries must consider not only the product but also the values and expertise of the company behind the wire. In doing so, they contribute to welding’s enduring legacy of strength and precision.