Logosweld’s Cutting-Edge Welding Electrode Machinery

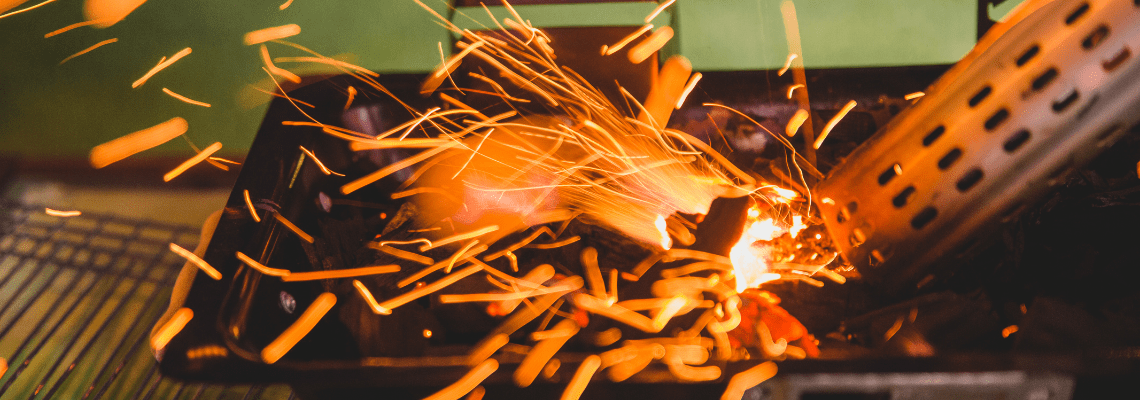

The welding industry forms the backbone of numerous sectors, from construction to manufacturing. At the heart of every successful weld is the welding electrode, a vital component that demands precision and consistency. Logosweld Company, a distinguished name in welding technology, has been at the forefront of innovation in the production of welding electrode machinery. In this article, we delve into Logosweld’s cutting-edge welding electrode machinery, exploring how it’s reshaping the industry.

The Role of Welding Electrode Machinery

Welding electrodes are essential consumables used in various welding processes. They conduct the electric current necessary for creating the arc, while the flux coating ensures a stable arc, removes impurities, and shields the weld from the atmosphere. To meet the high demand for quality welding electrodes, manufacturers require state-of-the-art machinery that combines efficiency with precision.

Logosweld’s Commitment to Excellence

Logosweld Company has earned a reputation for its unwavering commitment to producing top-of-the-line welding electrode machinery. Their dedication to excellence is evident in every aspect of their equipment, from design to performance. Here’s what sets Logosweld apart in the industry:

1.Advanced Technology

Logosweld’s machinery incorporates cutting-edge technology, ensuring optimal electrode quality and production efficiency. Their equipment is equipped with features like automatic electrode alignment, flux coating, and diameter control.

2. Precision Engineering

Precision is paramount in electrode manufacturing. Logosweld’s machinery is engineered to deliver consistent electrode diameter, flux coating thickness, and straightness, minimizing defects and ensuring high-quality welds.

3.Customization

Recognizing that different manufacturers have unique needs, Logosweld offers customization options. Whether you need equipment for small-scale production or high-volume manufacturing, they can tailor a solution to suit your requirements.

4.User-Friendly Design

Logosweld’s machinery is designed with user-friendliness in mind. Operators can easily set parameters, monitor production, and troubleshoot, minimizing downtime and maximizing productivity.

5.Efficiency and Cost Savings

Logosweld’s machinery not only enhances product quality but also contributes to cost savings through reduced waste and increased production efficiency. Their commitment to energy efficiency also aligns with sustainability goals.

Logosweld’s Product Range

Logosweld offers a diverse range of welding electrode machinery to cater to various production scales and requirements:

1.Welding Electrode Extrusion Press

This press is designed to extrude the electrode’s core wire and apply flux coating simultaneously, ensuring uniform thickness and superior quality.

2.Welding Electrode Coating Machine

Logosweld’s coating machines provide precise control over flux coating, ensuring a consistent and high-quality finish.

3.Wire Straightening and Cutting Machine

In addition to electrode-specific machinery, Logosweld also manufactures wire straightening and cutting machines to prepare the core wire with precision.

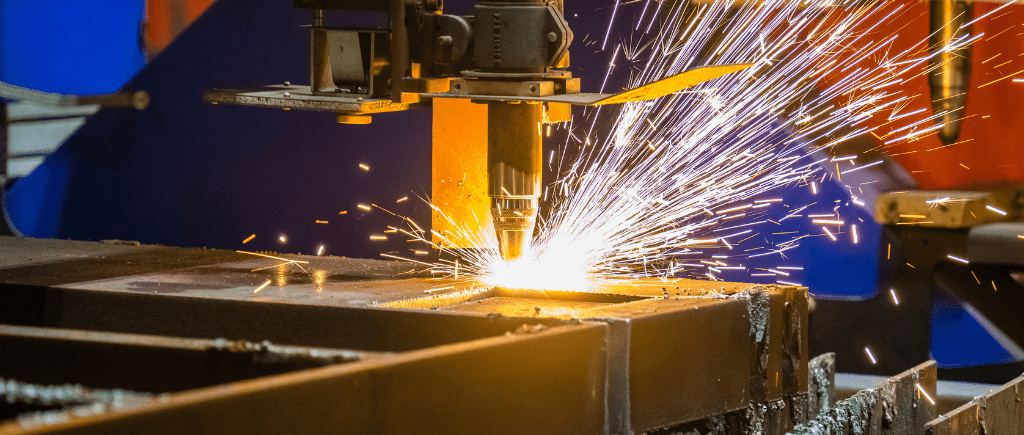

The Impact on Welding Industry

Logosweld’s welding electrode machinery has a profound impact on the welding industry:

1.Enhanced Productivity

The efficiency and precision of Logosweld’s machinery translate into higher productivity and reduced downtime for manufacturers.

2.Improved Weld Quality

With consistent electrode dimensions and flux coating thickness, weld quality is enhanced, resulting in stronger and more reliable welds.

3.Cost Savings

Reduced material wastage and energy-efficient machinery contribute to cost savings for manufacturers.

4.Global Reach

Logosweld’s commitment to quality has earned them a global clientele, strengthening the reputation of welding electrode manufacturers worldwide.

5.Sustainability

Logosweld’s focus on energy efficiency aligns with the growing emphasis on sustainability in manufacturing.

Conclusion

Logosweld Company’s welding electrode machinery is a game-changer in the welding industry. Their commitment to precision, efficiency, and innovation has revolutionized the production of welding electrodes, ensuring that manufacturers can consistently produce high-quality products. With a range of machinery catering to various production needs, Logosweld has become a trusted partner for welding electrode manufacturers worldwide. As the welding industry continues to evolve, Logosweld’s dedication to excellence paves the way for a brighter and more efficient future in welding electrode production.